Automatical line wire falling construction mesh welding machine

This machine cent-control and welding time are composed of PLC program system . The input front-panel has two forms, touch screen and keyboard that makes the machine more intelligent and reasonable and it could press at one time, separate welding. Surely,if the power supply is enough big,it can also adopt the welding at the same time.

- Commodity name: Automatical line wire falling construction mesh welding machine

- Commodity ID: 1023950153553108992

- 产品描述

-

Main Parameters:

Item

WZ-1200A

WZ-1500A

WZ-2000A

WZ-2500A

WZ-3000A

Number of Electrodes

24

30

40

50

60

Max.Mesh Width

≦1200mm

≦1500mm

≦2000mm

≦2500mm

≦3000mm

Wire Diameter

3.0-6.0mm

3.0-6.0mm

3.0-6.0mm

3.0-6.0mm

3.0-6.0mm

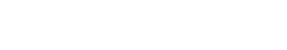

Cross Wire Space

50-250mm

50-250mm

50-250mm

50-250mm

50-250mm

Line Wire Space

50-200mm

50-200mm

50-200mm

50-250mm

50-250mm

Pulling Mesh Way

Servo Motor

Servo Motor

Servo Motor

Servo Motor

Servo Motor

Electric Capacity

125KVA*3

125KVA*4

125KVA*5

125KVA*6

125KVA*8

Welding Speed

50-70t/min

50-70t/min

50-70t/min

50-70t/min

50-70t/min

Line Wire Feeding Way

By the Special Electric Hopper

Cross Wire Feeding Way

By the Special Electric Hopper

Control System

PLC control and Touch Screen

Function features and advantages:

1.This machine cent-control and welding time are composed of PLC program system . The input front-panel has two forms, touch screen and keyboard that makes the machine more intelligent and reasonable and it could press at one time, separate welding. Surely,if the power supply is enough big,it can also adopt the welding at the same time.

2.Cross hopper feeds cross wires automatically with accurate position,pre-cut line wires fall and feed automatically from the special hopper, reduces welding waiting time, feed fast and locate accurately.

3.Our transformers adopts big power at 125KVA every one,which can ensure the welding quality in good condition and adopt water cooling system.

4.The greatest advantage is that you can adjust the distance of cross wire at random on the same one piece wire mesh sheet very easily, and only need to set the any space required on the touch screen.

5.Pulling mesh way adapts servo motor back and forward according to the setting parameters into the touch screen,ensure the accurate position of the pulling mesh.

Key words:

Get Quote

Note: Please leave your contact information, and our professionals will contact you as soon as possible!